Mechanical Construction

Utilize the Latest Technology | Since 1980 | Highly Skilled Professionals

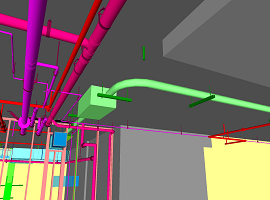

Utilize the Latest Technology

Since 1980

Highly Skilled Professionals

Hours:

In Business Since 1980

Douglas L. Munter formed Midlands Mechanical, Inc on April 10, 1980. The mission of Midlands Mechanical, Inc was to offer skilled craftsmen and top construction management throughout the Midwest. The company has grown from the original group to over 100 people, all of which are spread throughout the Midwest serving local communities.

Over 70% of our work is done by our own team, and the majority of our projects are repeat business - we impress our customers at every opportunity! Our professional craftsmen and managers meet aggressive schedules with excellent time management and quality results. Count on a team with over 350 years of combined experience. Call us today to get your project off the ground.

Here's what our satisfied clients are saying...

OMAHA, NE LOCATION